– Arnold H. Glasow

– Levi Strauss

At Accent Truss, we strive to create the best experience for our clients as possible. You’ll find information here that we hope you find helpful regarding our process, timing, design, assembly and installation, wood species and surface finishes. Every project has its own unique characteristics and requirements but each one we craft will have fantastic visual impact, small tolerances and delivery in a timely manner. Exceeding our clients’ expectations is always the top priority; repeat business is our barometer to measure success.

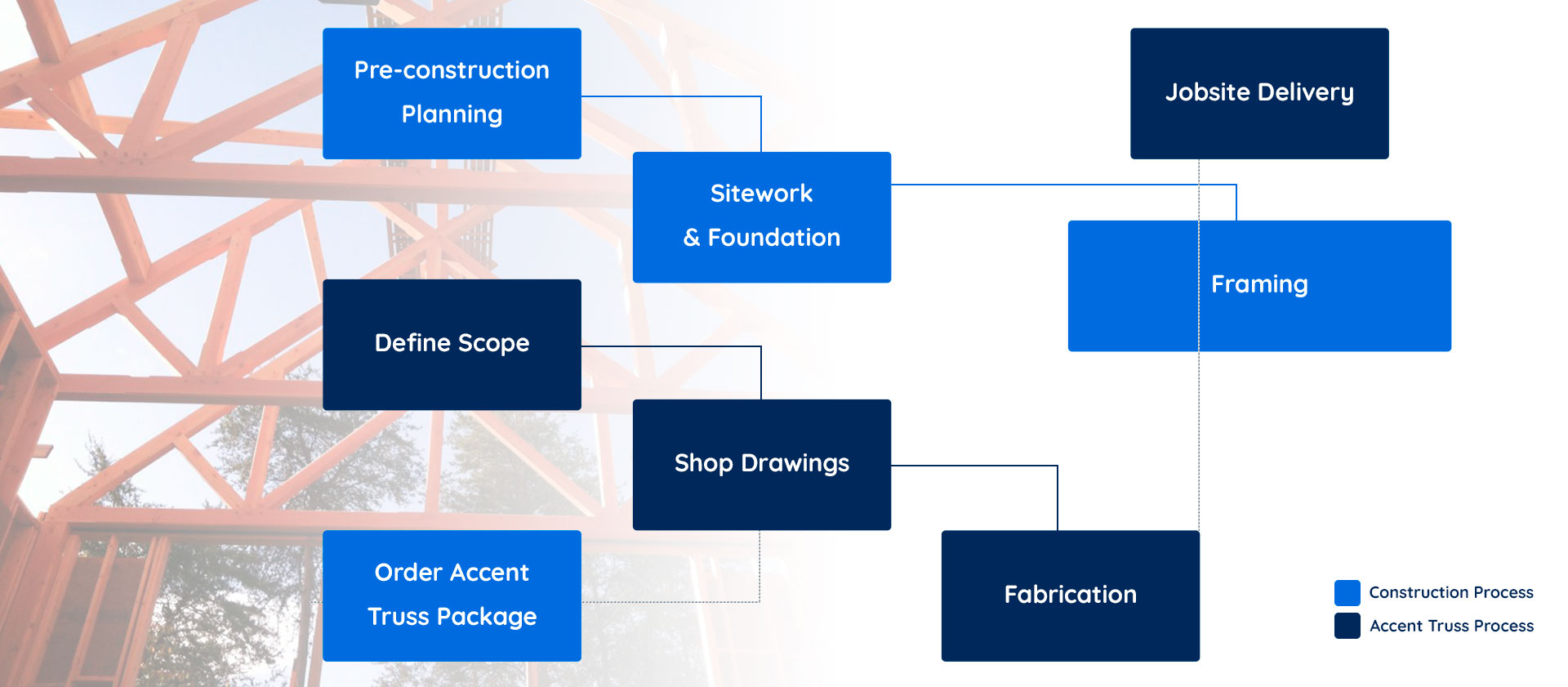

The best way to have timber trusses and components incorporated into a project is to work with us early as a partner in the process. This allows us to provide the quality service and craftsmanship we are known for and take pride in. The image below shows an ideal scenario for blending our process with yours.

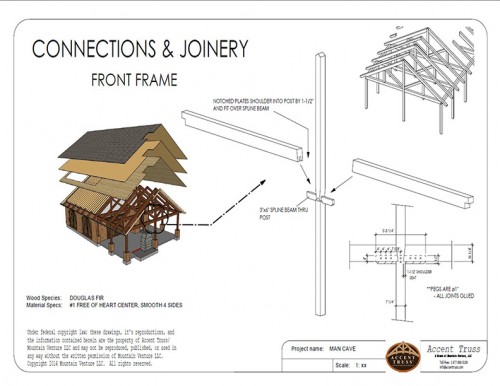

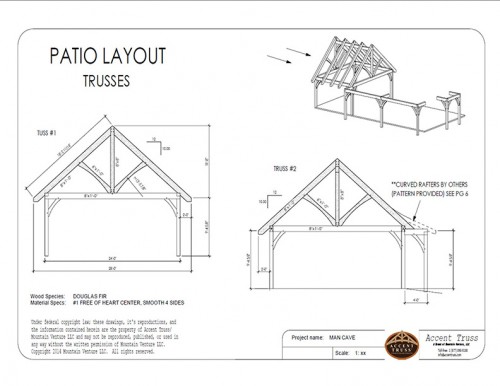

We pre-assemble each piece in the shop during the crafting and fabrication process to ensure a good fit on the jobsite. While some components will arrive to your jobsite assembled, many are too large and will be knocked down and bundled for shipping. We ship nationwide.

We do not do the jobsite assembly and/or installation, but we do make it as simple as possible for your onsite crews to perform this work by providing assembly drawings that clearly show how each piece goes back together and in what order to install.

Western Red Cedar (Scientific name: Thuja plicata)

Douglas Fir (Scientific name: Pseudotsuga)

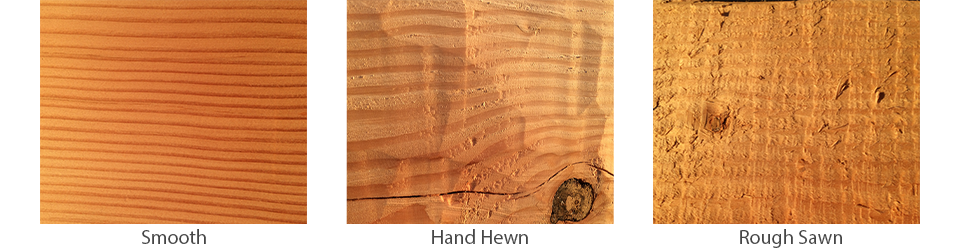

The surface of the material has a big impact on the overall visual appearance and style of the project. Smooth is the most “refined” look, and hand hewn or rough sawn tend to be more rustic. Many projects have a mixture of textures. Smooth for interior timbers and rough sawn for exterior is the most common combination. The advantage of smooth timber for the interior is keeping it clean. It’s much easier to brush dust and cobwebs off a smooth timber. Exterior timber will show weather over time, but rough sawn or hand hewn has a more rustic look initially and weathering will not show nearly as much in years to come.

Every project is unique and scope and size will affect lead time as will what other projects we are crafting at the time you place your order. Generally speaking, though, most projects carry an 8-10 week lead time from when we receive your contract and deposit payment. Some smaller projects can be done in 6-8 weeks and larger ones can take as long as 12-14 weeks.

Purchase agreements are written for each project that describe the scope of work and contract price. The total contract price is generally split into three equal payments. The first payment is a deposit due at the time of signing the purchase agreement. This gets your project into the schedule and our resources dedicated to producing shop drawings. The second payment coincides with the submission and approval specific to your project will be ordered from the sawmill and delivered to our shop for fabrication. As crafting and fabrication nears completion the final invoice will be sent out and once payment is received the shipping arrangements can be made. Due to the custom nature of what we craft (no two packages are alike) all payments are made prior to shipment to the site.

Providing our clients with exceptional service is what we strive to do. We have many terrific clients and we’re happy to have you talk to them about their experiences working with us! Please feel free to contact us at acct@accenttruss.com or call (877) 898-5108 and request references.

– Frank Gehry